The Role of PCB Fabrication in Singapore’s Electronics Industry

Behind every smartphone, sensor, or server lies a printed circuit board, quietly doing the heavy lifting. In Singapore, a country known for its efficient systems and precise standards, PCBs are more than layers of copper and laminate. They are the stage where electrical components play in harmony. Without them, the gadgets in homes and factories would be little more than loose parts in a box. The demand for reliable boards has put PCB fabrication in Singapore in a position where its output underpins many industries.

From Design to Production

The journey of a PCB begins as a design file, carefully plotted with layers of pathways. Once passed to a manufacturer, that design becomes reality through processes like copper etching, drilling, and plating. Each stage matters, as a single defect could mean a board that fails to conduct properly. Singapore’s manufacturers focus on consistency, where equipment accuracy and skilled oversight keep faults from sneaking in. For clients, this means greater trust in boards that form the skeleton of their devices.

Supporting Different Industries

Electronics in Singapore are not limited to consumer gadgets. Medical equipment, aerospace controls, and industrial machinery all rely on strong boards. The ability of local facilities to produce PCBs that withstand high temperatures, vibrations, and constant use gives them value in such sectors. As demand shifts, manufacturers adjust their lines, whether for high-density interconnect boards or simpler single-layer pieces. This flexibility ensures that clients from different sectors find solutions without having to look far afield.

Precision as a Standard

Singapore’s reputation for strict standards extends into electronics production. Factories handling PCB fabrication in Singapore adhere to international certifications like ISO 9001 and IPC guidelines. These frameworks are not marketing badges; they are essential in ensuring boards meet electrical and mechanical requirements. For businesses sourcing locally, compliance reduces risks of product recalls or system failures. The result is a supply of boards that consistently meet the expectations of global partners.

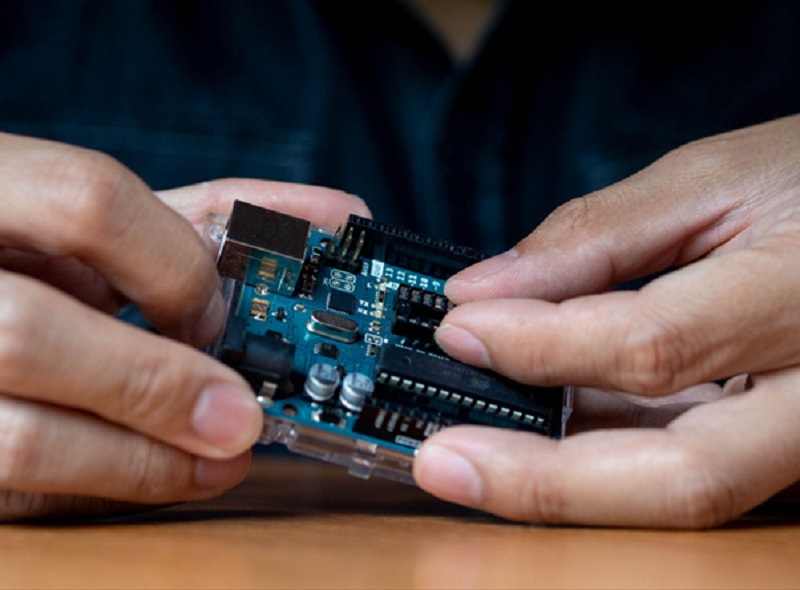

The Machinery Behind the Magic

Though no wands are waved in production halls, the machinery does feel impressive. Automated drills, pick-and-place systems, and reflow ovens are everyday tools that keep throughput steady. Quality checks, including automated optical inspection and flying probe tests, help detect errors that even sharp human eyes might miss. The mix of machinery and skilled technicians is a balance that ensures speed does not come at the cost of quality.

Supply Chains and Stability

No board exists without materials, and global disruptions have shown how fragile electronics supply chains can be. Singapore’s location and infrastructure give it an advantage in maintaining smoother flows of copper, laminates, and components. Local manufacturers also cultivate ties with multiple suppliers to keep their lines running. This attention to logistics helps them deliver on time, which is vital for businesses working on tight schedules.

Moving Towards Sustainable Practices

Environmental awareness has reached PCB production as well. Traditional methods use chemicals and energy in ways that raise concerns. Some facilities in Singapore have begun adopting greener practices, such as recycling copper, improving water treatment, and exploring eco-friendly solder masks. These steps may not change the entire industry overnight, but they show that board fabrication can adapt to meet broader environmental goals without losing efficiency.

Why Businesses Value Local Fabrication

For businesses in Singapore, sourcing boards locally offers several advantages. Faster turnaround, clear communication, and the ability to visit production sites make the process more transparent. Local fabrication also supports the wider electronics ecosystem, linking designers, suppliers, and manufacturers together in one city-state. Having access to reliable boards nearby shortens the time between idea and product, which is essential in competitive markets.

Looking Ahead

The future of PCB fabrication in Singapore will likely see boards becoming denser and more specialised. While global competition remains strong, the city-state’s strength lies in its focus on quality and adaptability. Whether supporting research prototypes or producing batches for established industries, Singapore’s manufacturers are positioned to remain vital players. For businesses weighing their options, the choice often comes down to trust, and that is a currency local facilities have built steadily over time. Contact MPN Tech to find out how your business can benefit from reliable PCB fabrication and a steady electronics supply chain.